호스 용 플라스틱 클램프는 플라스틱의 다양한 특징과 결합되고 외관 조정에 의해 작용하는 힘을 변환하기 위해 정밀한 치아 유형 구조로 잘 설계된 강한 메쉬를 가진 새로운 유형의 구조 패스너입니다. 구조. 플라스틱 호스 클립은 나사 및 너트, 금속 호스 클램프 및 로프 등과 같은 전통적인 패스너를 대체 할 수있는 연결, 고정 및 밀봉 튜브에 일반적으로 사용되는 새로운 유형의 액세서리입니다. 또한 쉬운 고정, 강한 힘, 좋은 밀봉, 편리한 분해, 재활용 및 높은 비용 성능의 장점으로.

런즈판매를위한 품질 플라스틱 호스 클램프를 제공하며, OEM 견고한 호스 클램프는 완전히 지원됩니다.

Model No. (New) | Material | Color | Adapted Diameter (mm) | Product Width (mm) |

1000000001 | POM | White | 3.8-4.3 | 22 |

1000000004 | 4.3-4.8 | 22 | ||

1000000003 | 4.9-5.4 | 22 | ||

1000000024 | 5.5-6.0 | 22 | ||

1000000010 | 6.0-6.5 | 22 | ||

1000000002 | 6.5-7.0 | 23 | ||

1000000013 | 7.0-7.5 | 24 | ||

1000000005 | 7.5-8.0 | 24 | ||

1000000006 | 8.0-8.5 | 26 | ||

1000000018 | 8.6-9.1 | 26 | ||

1000000012 | 9.1-9.6 | 26 | ||

1000000007 | 9.6-10.2 | 25 | ||

1000000008 | 10.2-10.7 | 26 | ||

1000000015 | 10.7-11.2 | 25 | ||

1000000016 | 11.1-11.6 | 25 | ||

1000000009 | 11.6-12.1 | 24 | ||

1000000011 | 12.0-12.5 | 26 | ||

1000000017 | 12.6-13.1 | 28 | ||

1000000023 | 12.3-14.0 | 25 | ||

1000000014 | 13.1-13.6 | 33 | ||

1000000022 | 13.7-14.2 | 28 | ||

1000000025 | 14.2-14.7 | 27 | ||

1000000019 | 14.7-15.2 | 27 | ||

1000000020 | 15.2-15.7 | 27 | ||

1000000053 | 15.2-17 | 32 | ||

1000000055 | 21.5-23.5 | 40 | ||

| 1000000021 | 24.3-26.1 | 48 | ||

| 1000000026 | 35.5-37.5 | 51 |

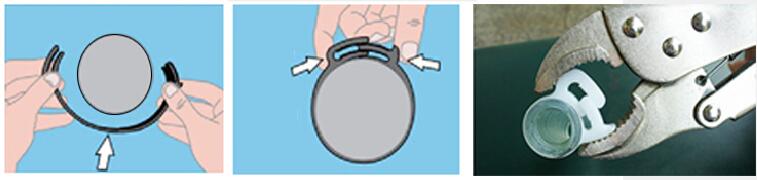

a. Connecting your tube fully into a connector

b. Use vernier calipers to measure the total diameter where you want to fix after tubing connected with connector (see above figure)

c. Choose a suitable model according to above-adapted Diameter listings

d. Slip the hose clamp until reaching the connector, then close the gear until it is tightly fastened

Clamp the outermost tooth with a wire-cutter (please don't clamp left and right tooth together), move flatly and gently as the tooth slot, fleetly twist it with small angle(upper and nether tooth misplaced), then it will be loosened, Please note keep small angle when twisting to ensure the tooth non-deformed when misplaced it is reusable.

Solutions for Common Problems

1. Checking the fastening effect

Rotate the hose clamp manually to ensure it is tightly fastened with no blind side, good sealing and a smooth fastening surface.

2. Leakage and shed after pressured

a. Leakage after pressed includes many caused such as hose clamp with insufficient force, the diameter of the tube is far more than the outer diameter of the connector, a tube with insufficient flexibility, etc.

b. Shed after pressured includes two causes: one is surpassing limit pressure of hose clamp with inner tooth prop up the outer tooth, multi-tooth lose common mesh (only rely on the main tooth); another is the friction force between tube shed off (head part is still fastened). The solution is to choose the right specification or simultaneously use two pieces of hose clamps (head part should be placed at two places, or it will be hard to disassemble)